INDIA OFFICE

| No.111, SIDCO AIEMA TOWER, 1ST MAIN RAOD, | ||

| AMBATTUR INDUSTRIAL ESTATE, | ||

CHENNAI - 600058, TAMILNADU, INDIA. | ||

TEL NO | : | +91-44-4863 2548 |

FAX NO | : | +91-44-4863 2549 |

MOBILE NO | : | +91-85266 14246 / 80122 23576 |

: | +91-99621 42548 | |

: | sales@sarancorporation.co.jp | |

Skype | : | sarancoindia |

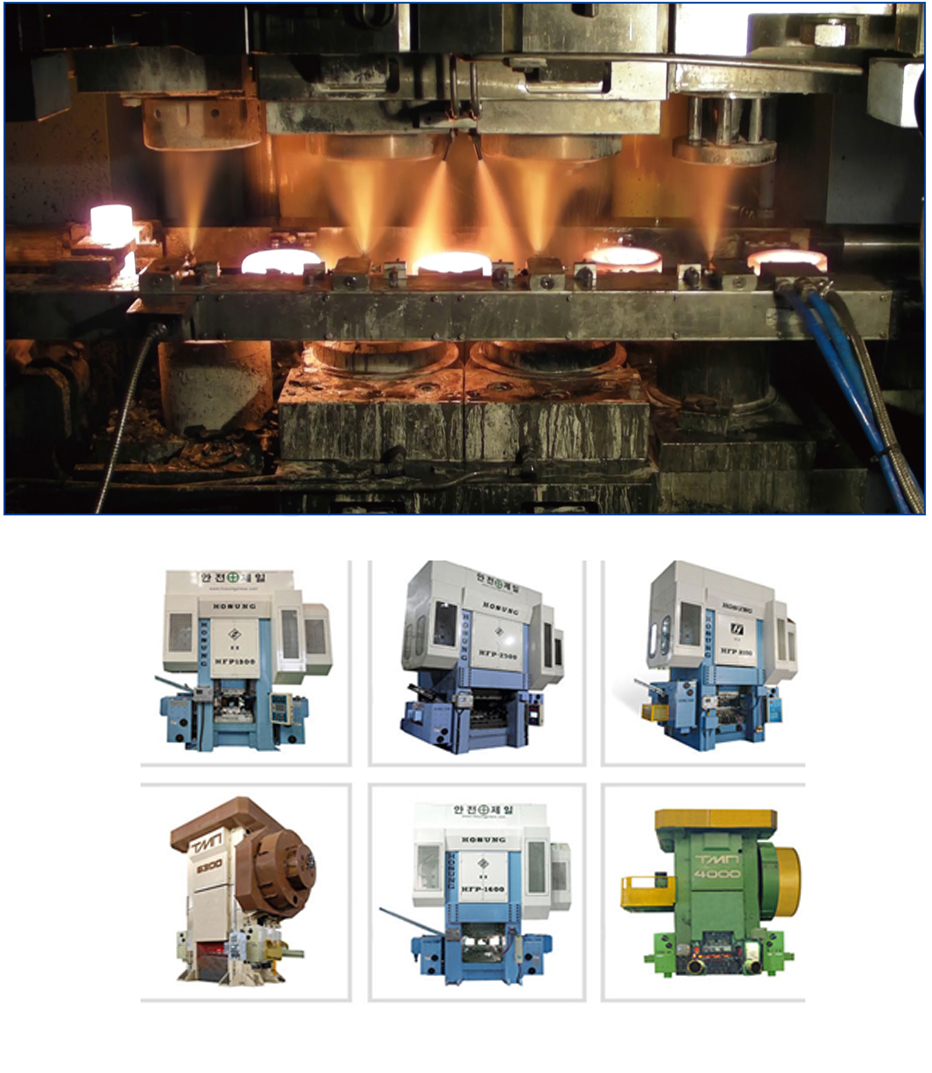

View Product Catalog

View Product Catalog